What is Fiber Laser Cutting? Definition, Process, Parameters & Types

- July 4, 2025

- Cnc Laser Bending Fibre Laser Cutting

- Hepta Engineering.com.pk

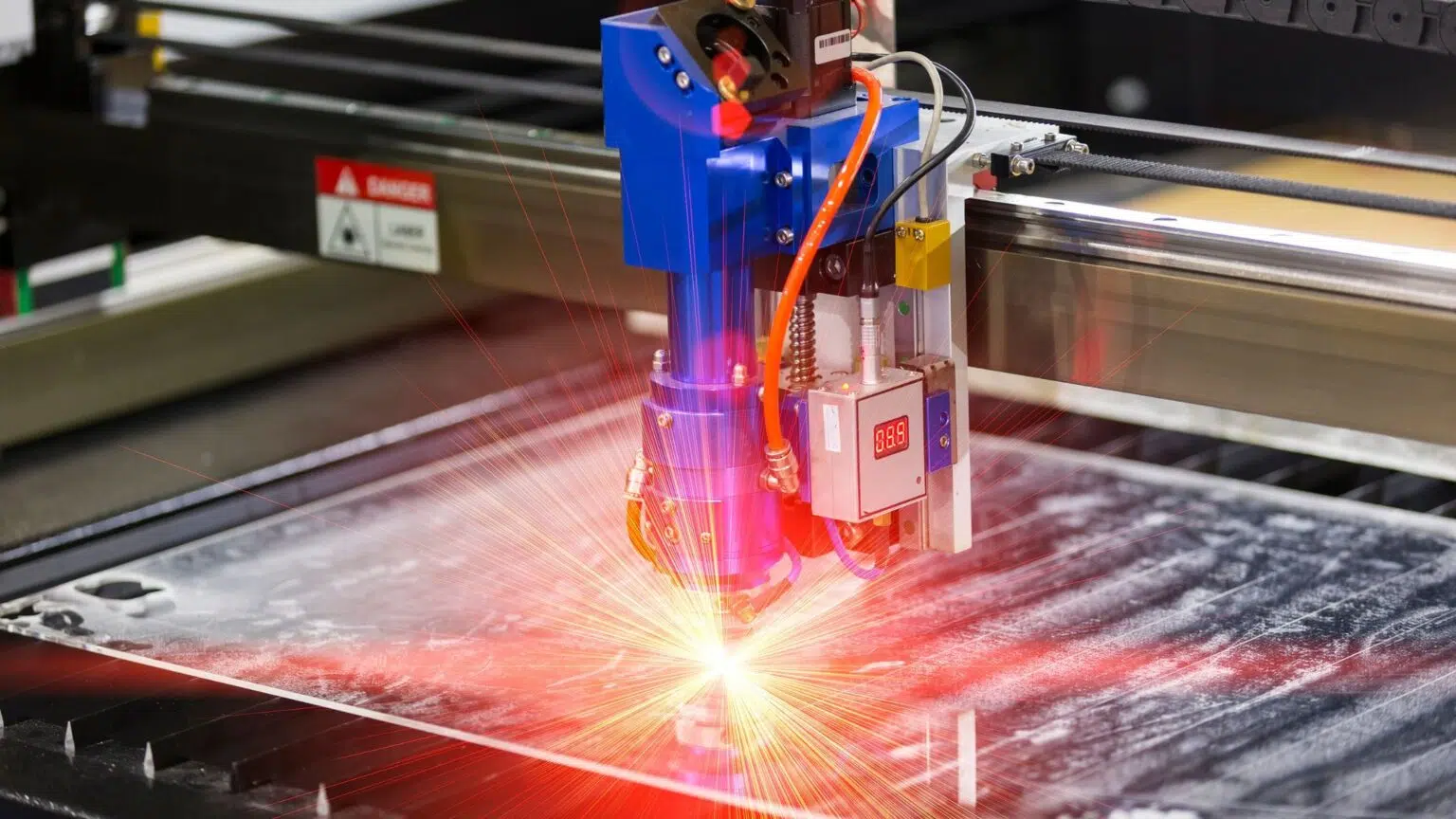

Fiber laser cutting is revolutionizing the metal fabrication industry with its speed, precision, and efficiency. From automotive to aerospace, this advanced technology is shaping the future of manufacturing. In this guide by Hepta Engineering, we’ll explain the definition, process, key parameters, and types of fiber laser cutting—so you know why it’s a smart investment for modern industries.

What is Fiber Laser Cutting?

Fiber laser cutting is a thermal cutting process that uses a focused, high-powered laser beam to melt or vaporize material, usually metals, with extreme accuracy. The laser is generated through fiber optic cables, which offer better beam quality and energy efficiency than traditional CO₂ lasers.

At Hepta Engineering, we offer cutting-edge fiber laser cutting machines designed for optimal performance in industrial applications.

How Does the Fiber Laser Cutting Process Work?

The fiber laser cutting process involves several critical steps:

Laser Generation: The fiber laser source produces a concentrated beam of light via diodes and fiber optics.

Beam Delivery: The laser beam is transmitted through a lens system to the cutting head.

Material Interaction: The beam focuses on the metal surface, heating it to the melting or vaporization point.

Assist Gas: A stream of gas (often nitrogen or oxygen) blows away molten material, ensuring a clean cut.

Motion System: CNC controllers guide the laser along the desired cutting path with micrometer precision.

Key Parameters of Fiber Laser Cutting

To achieve the best results, certain parameters must be optimized:

Laser Power (e.g., 1kW, 3kW, 6kW): Higher power enables faster cutting and thicker materials.

Cutting Speed: Must be adjusted based on material type and thickness.

Focus Position: Determines cut quality and kerf width.

Assist Gas Type and Pressure: Affects oxidation and edge smoothness.

Pulse Frequency (in pulsed mode): Crucial for materials like aluminum or copper.

At Hepta Engineering, our machines come with smart interfaces to easily adjust fiber laser cutting parameters for precise results.

Types of Fiber Laser Cutting

There are several types of fiber laser cutting, each suited for different applications:

1. Flatbed Fiber Laser Cutting

Used for sheet metals

Ideal for industries like automotive, HVAC, and furniture

2. Tube & Pipe Laser Cutting

Designed to cut round, square, and custom-shaped tubes

Widely used in construction and machine manufacturing

3. 3D Fiber Laser Cutting

Used for complex shapes, curved surfaces, and automation lines

Common in aerospace and robotics

4. High-Power Fiber Laser Cutting

Offers deep cuts in thick steel or alloy materials

Used in heavy industries and shipbuilding

Hepta Engineering provides machines tailored to all these types, ensuring maximum flexibility for your business needs.

Advantages of Fiber Laser Cutting

High precision and tight tolerances

Faster cutting speeds than traditional methods

Low maintenance and long lifespan

Energy-efficient operation

Capable of cutting reflective materials like brass and copper

With Hepta Engineering’s fiber laser cutting machines, you’ll enjoy better productivity and lower operational costs.

Why Choose Hepta Engineering?

At Hepta Engineering, we combine German-grade engineering with local support to deliver top-performing fiber laser cutting solutions. Our machines are trusted by manufacturers across Pakistan and the Middle East for:

Custom cutting systems

On-site installation and training

24/7 technical support

Affordable financing options

Final Thoughts

Fiber laser cutting is more than just a technology—it’s a competitive edge in modern manufacturing. Whether you’re working with sheet metal, tubes, or complex 3D components, Hepta Engineering offers the precision, power, and reliability your operations demand.

Need Help

?

Have questions or need assistance? Our team is ready to help with expert guidance and support.